Product Specifications

| Model No.: | NEW ENERGY RESOURCES PNEUMATIC CYLINDER LINER SEAL RING | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

Product Features

In the core structure of new energy vehicle braking systems, the cylinder liner serves as a critical load-bearing component within the cylinder accessories system. Its accompanying cylinder seal rings directly undertake the sealing and pressure transmission tasks of high-pressure oil. As essential precision cylinder accessories, the coordinated operation of the cylinder liner and cylinder seal rings not only ensures zero brake fluid leakage but also significantly enhances the response speed of energy recovery systems through optimized pressure transfer efficiency.

From a functional classification perspective, braking components paired with the cylinder liner include four major types such as rubber diaphragms and hydraulic cups. Among these, cylinder seal rings act as dynamic sealing units within cylinder accessories, where material selection directly impacts system reliability. Current mainstream black cylinder seal rings utilize carbon fiber-reinforced rubber composites, maintaining elastic modulus stability in temperatures ranging from -40°C to 150°C. Yellow variants, enhanced with polyimide modifiers, enable these cylinder accessories to sustain over 8,000 hours of durability in highly corrosive environments. Notably, in specialized applications like oil-free compressors, cylinder liner systems are equipped with polytetrafluoroethylene (PTFE)-based cylinder seal rings, achieving a dry friction coefficient below 0.05.

As a paradigm of innovation in cylinder accessories, the latest-generation cylinder liner assemblies optimize the contact stress distribution of cylinder seal rings via 3D simulation technology. Our test data reveal that cylinder seal rings featuring wave-lip designs improve sealing surface contact pressure uniformity by 47%. When combined with laser micro-texturing technology on the cylinder liner's inner wall, the entire cylinder accessories system achieves a braking response time reduced to 0.15 seconds. This innovative design decreases wear rates by 62% under frequent start-stop conditions, substantially extending the service life of cylinder accessories.

To meet diverse vehicle compatibility requirements, we offer modular customization services for cylinder liners and cylinder seal rings: passenger vehicle versions employ lightweight aluminum alloy cylinder liners paired with slim-profile sealing components, while commercial vehicle-specific cylinder accessories integrate reinforced cast iron bases with multi-layer steel-skeleton sealing rings, capable of withstanding transient impact pressures exceeding 35 MPa. All cylinder seal rings comply with ISO 3601 hydrodynamic sealing international certification, ensuring every cylinder accessory maintains sealing integrity under extreme thermal cycling tests.

With 20 years of expertise in cylinder liner systems, our cylinder accessories solutions have supported 12 global new energy vehicle manufacturers. From molecular material structure design to dynamic sealing simulations for cylinder seal rings, we have established a comprehensive cylinder liner technical database. This enables rapid delivery of customized cylinder accessories engineering solutions tailored to client needs, driving continuous evolution of braking systems toward greater safety and efficiency.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

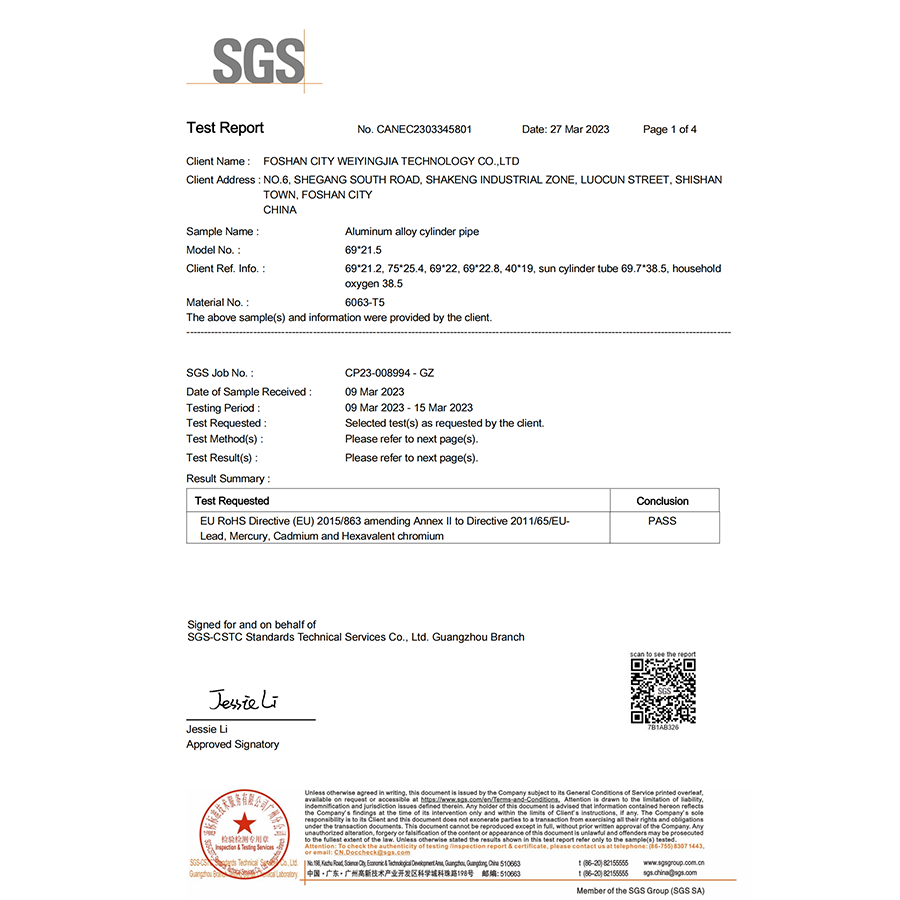

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE