Product Specifications

| Model No.: | PRECISION HYDRAULIC SEAMLESS PIPE HONING TUBE | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

About Us

High-Precision Honing Tube: The Core Component for Pneumatic Hydraulic Systems

The honing tube, a vital element in pneumatic hydraulic applications, is crafted from high-strength seamless pipe through cold drawing and precision honing. With ultra-smooth inner surfaces (Ra0.2μm) and dimensional accuracy (±0.02mm), this seamless pipe-based component reduces friction and pressure drops, making it essential for hybrid pneumatic hydraulic systems in robotics, industrial automation, and heavy machinery.

In pneumatic hydraulic cylinders, the honing tube withstands combined pneumatic and hydraulic pressures (40MPa+). Its seamless pipe structure eliminates weld weaknesses, while honing ensures leak-free performance. For example, automated production lines use honing tubes to synchronize pneumatic speed with hydraulic force, while energy recovery systems leverage customized seamless pipe designs (e.g., tapered bores) to optimize fluid-air interaction.

Material Durability: Cold-formed seamless pipe provides ≥600MPa tensile strength, heat-treated to endure pneumatic hydraulic cyclic loads.

Surface Precision: Multi-stage honing achieves <0.1mm/m straightness in honing tubes, outperforming standard seamless pipe and reducing hybrid seal wear.

Adaptive Design: Wall thickness, diameter, and surface coatings (e.g., nitriding) are customizable, ensuring honing tubes meet diverse pneumatic hydraulic requirements—from compact actuators to high-power hybrid drives.

Selection: Choose stainless steel seamless pipe-based honing tubes for moisture-rich pneumatic hydraulic environments.

Installation: Degrease and inspect honing tubes to prevent contamination in hybrid systems.

Maintenance: Monitor inner walls for pitting (>0.05mm depth) caused by air-liquid mixtures.

Storage: Avoid stacking seamless pipe-derived components horizontally to prevent ovality.

Conclusion

As a fusion of air and fluid power evolves, honing tubes—rooted in robust seamless pipe technology—empower pneumatic hydraulic systems to achieve unprecedented efficiency and control. Their design rigor addresses the unique challenges of hybrid actuation, solidifying their role in next-generation industrial innovation.

About Us

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

About Us

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

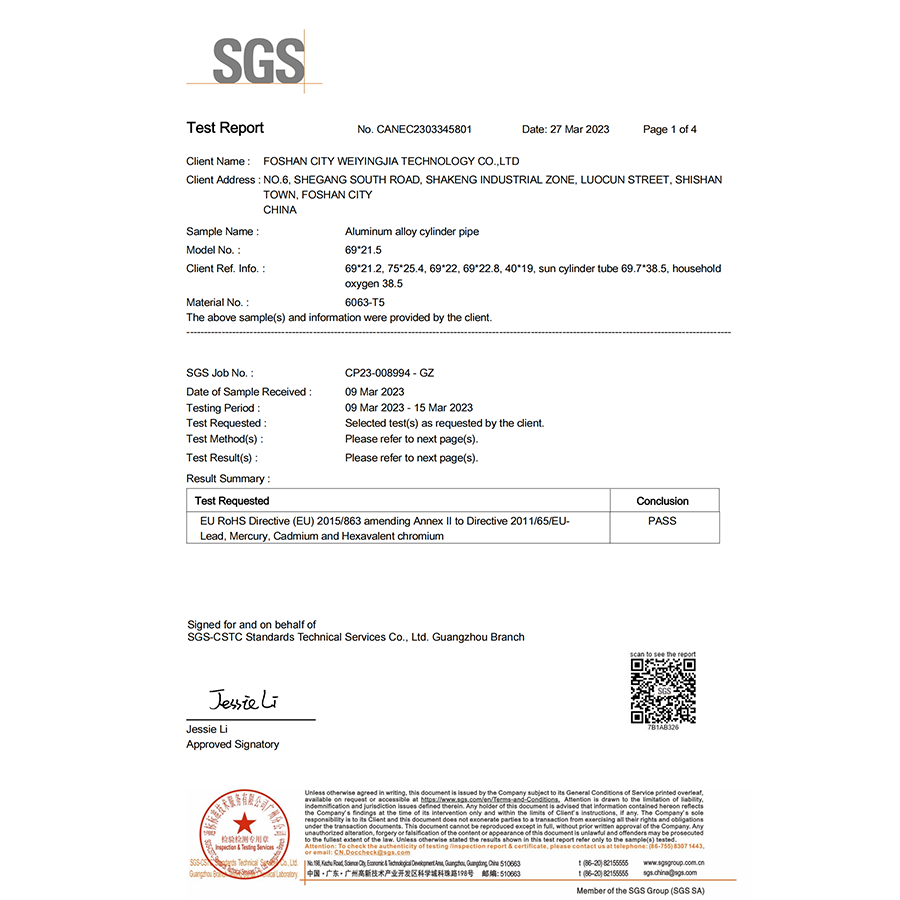

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE