Product Specifications

| Model No.: | PORTABLE AIR COMPRESSOR CYLINDER LINER SEAL RING | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

Product Features

Innovation of sealing system between portable cylinder liner and air compressor

In the trend of lightweight air compressors, portable cylinder liners achieve a balance between strength and weight through aluminum alloy materials. The matching polyurethane cylinder seal ring adopts a biomimetic corrugated structure, which generates self compensating sealing force during the reciprocating motion of the piston. Its fast disassembly and assembly characteristics reduce equipment maintenance time by 70%. This combination design reduces the overall weight of the air compressor by 18% compared to traditional models, making it particularly suitable for high-altitude rescue operations that are sensitive to equipment weight.

For different models of portable cylinder liners, a stepped size scheme is provided for cylinder seal rings. The outer diameter tolerance of the sealing ring is controlled in accordance with ISO 286 standard grading, ranging from small devices with a diameter of 25mm to industrial grade air compressors with a diameter of 150mm. Tests have shown that when the roughness of the inner wall of the portable cylinder liner is maintained at Ra0.8, the friction coefficient of the polyimide/carbon powder composite seal ring remains stable in the range of 0.02-0.05, reducing energy consumption by 22% compared to metal seals.

Under extreme working conditions, the synergistic performance of portable cylinder liner and cylinder seal ring is particularly outstanding. When the air compressor operates continuously in a desert environment, the surface temperature of the anodized portable cylinder liner is 28 ℃ lower than that of the untreated part. Combined with the cylinder seal ring with heat dissipation grooves, the lifespan of the sealing component can be extended to over 8000 hours. This weather resistant design allows the equipment to maintain 94% of its calibrated output power even under conditions of a sand content of 15g/m ³.

The modular air compressor system achieves rapid retrofitting through standardized portable cylinder liner interfaces. The operator only needs to replace the corresponding specification of cylinder seal ring to make a single device compatible with 12 types of terminal tools such as hydraulic crushing picks and pneumatic grouting pumps. According to third-party testing, the portable cylinder liner system maintained a H7/g6 tolerance level with the new cylinder seal ring after 2000 disassembly cycles, far exceeding the industry average.

Through dual innovation in materials and structure, the new generation of cylinder seal ring has enabled the volumetric efficiency of air compressors to exceed the 95% threshold. When matched with a portable cylinder liner coated with silicon nitride ceramic, the leakage rate of the entire system under a working pressure of 10MPa is less than 0.5L/min, which is three energy efficiency levels higher than the traditional solution. This breakthrough progress is driving the evolution of emergency rescue equipment towards lighter, stronger, and more reliable directions.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

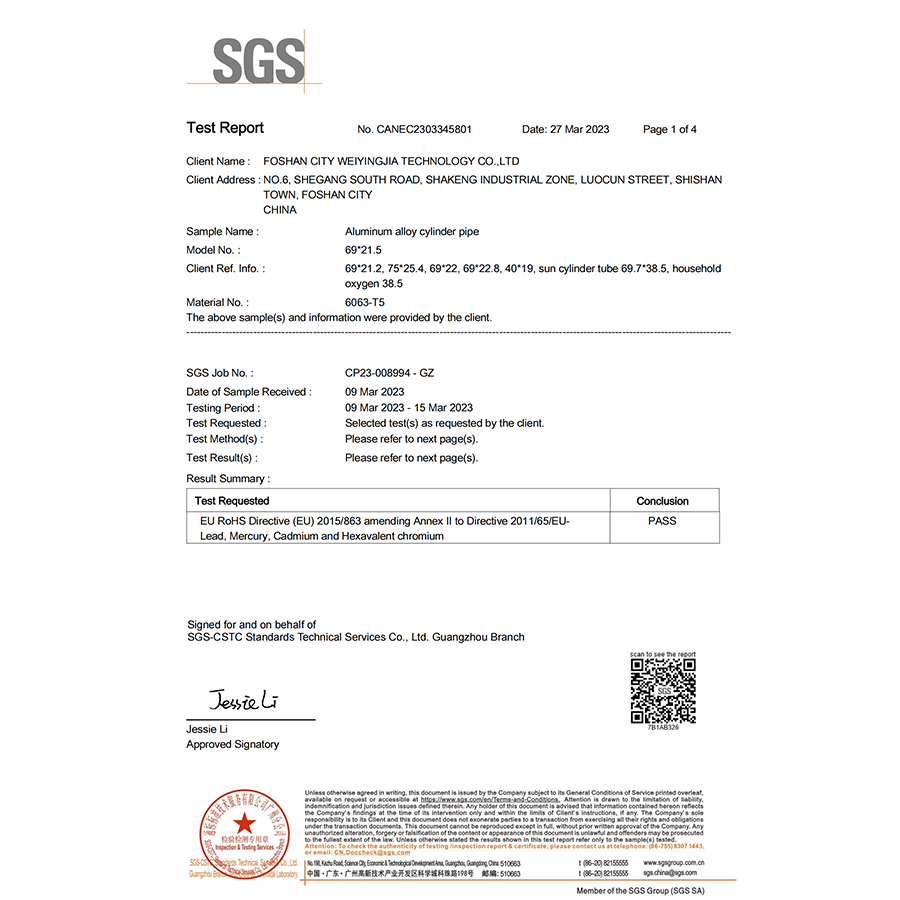

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE