Product Specifications

| Model No.: | REGULAR AIR COMPRESSOR CYLINDER LINER SEAL RING | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

| Cylinder liner size | Seal ring size | |||

| φ28.5*φ23* 18.4 | 28.5*4*06 | |||

| φ30*φ26*20.5 | 26* 10*0.5 | |||

| φ35*φ30*22.5 | 30*20*0.6 | |||

| φ40*φ35*22.6 | 48*34.5*0.7/0.6 | |||

| φ55.6*φ50.8* 17 | 53.8*41.7*0.7/0.6 | |||

| φ63*φ57.8*20.2 | 62*48*0.7 | |||

| φ63*φ57.8*21.5 | 62*48*0.8 | |||

| φ69*φ63.7*21.5 | 68*48*0.8 | |||

| φ69*φ63.7*22 | 68*48* 1.0 | |||

| φ75*φ69.7*24.4 | 74.5*56.5* 1.0 | |||

| φ75*φ69.7*45.9 | 74.5*56.5* 1.2 | |||

| φ75*φ69.7*47.5 | 74.5*56.5* 1.5 | |||

Product Features

Nitrile rubber (NBR) standard sealing rings, as the core sealing component of the cylinder liner in air compressor systems, play an irreplaceable role in industrial equipment maintenance due to their oil resistance and temperature adaptability. This type of sealing ring strictly follows the ISO 6431 standard design and is compatible with different models of air compressor cylinders. Its basic working temperature covers -30 ° C to 100 ° C and is widely used for cylinder liner sealing repair in factory stamping machines, material conveying systems, and other scenarios, ensuring long-term stable operation of the equipment.

In the practical application of air compressors, the matching of cylinder liners and sealing rings needs to be based on temperature conditions as the core consideration. For example, a 550W air compressor requires sealing rings to withstand extreme temperatures ranging from -20 ° C to 250 ° C; In the 750W model, the sealing rings matched with the cylinder liner are adjusted to a temperature range of -10 ° C~150 ° C, while the high-power 1100 Wair compressor requires the sealing rings to maintain stable performance within the range of -15 ° C~220 ° C. This differentiated temperature requirement indicates that the collaborative design of cylinder liners and sealing rings directly affects the efficiency and lifespan of air compressors. If the selection is improper, high temperature may cause the hardening failure of sealing rings, while low temperature may cause brittle cracking of seals, leading to pressure leakage inside the cylinder liner.

It is worth noting that the application scope of sealing rings is not limited to industrial air compressors. In the automotive field, whether it is the hydraulic brake system of light cars or heavy trucks, the sealing rings in the cylinder liner are responsible for key pressure transmission and medium sealing tasks. For example, clutch control units and booster pump systems rely on high-precision sealing rings to achieve efficient conversion of fluid power, and the oil resistance and fatigue resistance of such seals are the core advantages of NBR materials. This cross disciplinary universality further confirms the reliability of sealing rings under complex working conditions, and also puts forward stricter requirements for the adaptation of cylinder liner sealing systems for air compressors and vehicle equipment manufacturers.

To maximize the performance of sealing rings, users need to regularly check the wear of the cylinder liner of the air compressor and replace the sealing components with appropriate specifications in a timely manner according to fluctuations in ambient temperature. For example, it is recommended to prioritize the use of heat-resistant sealing rings for air compressors in high-temperature workshops, while for low-temperature logistics and warehousing equipment, attention should be paid to the low-temperature elastic retention rate of cylinder liner seals. By accurately matching the sealing rings with the operating parameters of the air compressor, the maintenance cycle of the cylinder liner component can be significantly extended, and the comprehensive operation and maintenance cost of the equipment can be reduced.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

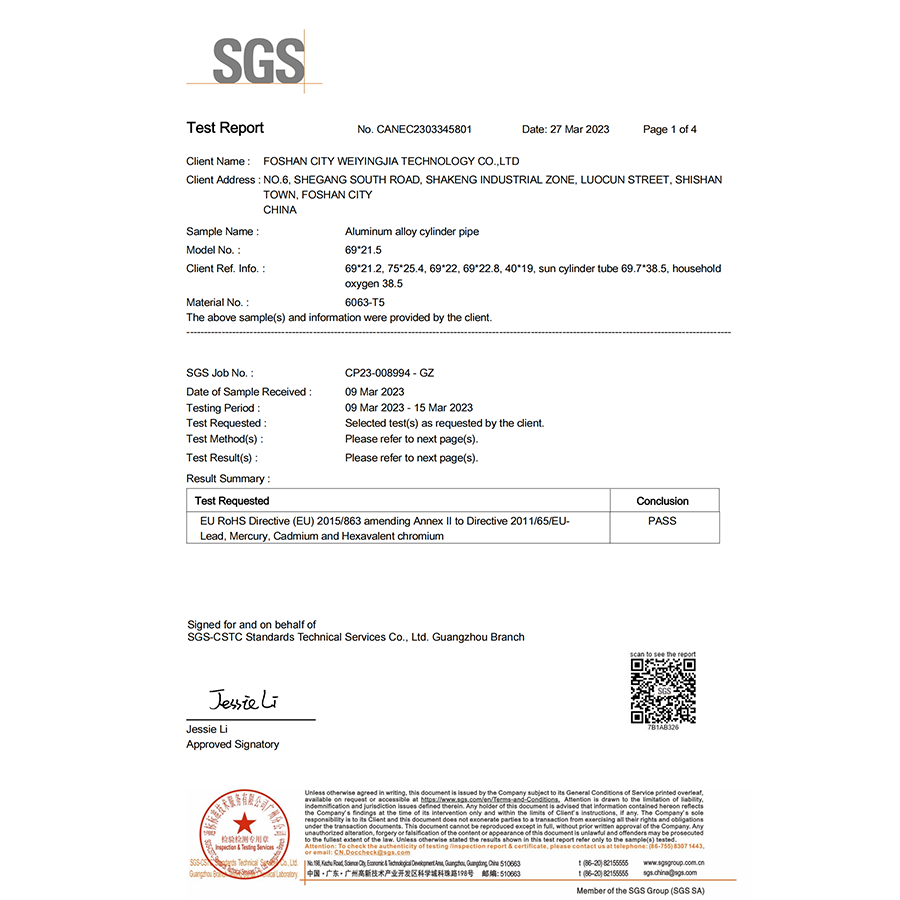

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE