Product Specifications

| Model No.: | OIL FREE COMPRESSOR PNEUMATIC ACCESSORY SET | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

Product Features

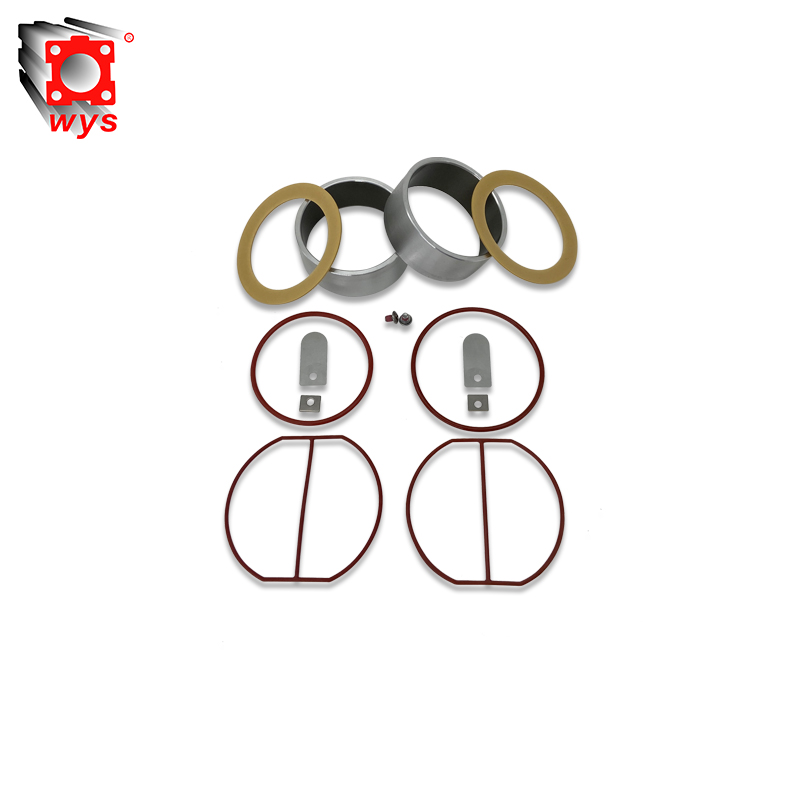

In industrial and precision equipment fields, oil-free compressors have become critical power sources due to their zero-pollution and low-energy advantages. To meet equipment maintenance needs, we introduce air cylinder accessories specifically designed for oil-free compressors. These air cylinder accessories include core components such as cylinders, diaphragms, valve plates, screws, and seals, enabling rapid replacement through modular design to ensure efficient operation of pneumatic accessory systems.

The air cylinder accessories are developed for the long-term stable operation of oil-free compressors, suitable for high-cleanliness scenarios like medical, food processing, and laboratories. Medical devices rely on oil-free compressors to deliver oil-free air for patient safety, while these air cylinder accessories eliminate oil contamination risks through precision seals and high-temperature-resistant valve plates. In industrial production lines, the durability of pneumatic accessory systems directly impacts efficiency. The high-strength cylinders and custom screws in the air cylinder accessories withstand continuous high-pressure operations, minimizing downtime losses. Additionally, applications of oil-free compressors in electronics manufacturing and spray coating require these air cylinder accessories to provide clean air, avoiding oil mist contamination of sensitive components.

As a professional pneumatic accessory solution, the air cylinder accessories achieve multiple breakthroughs in design and craftsmanship. First, all components are compatible with the oil-free lubrication system of oil-free compressors. Cylinders use aerospace-grade aluminum alloy for lightweight and corrosion resistance, while diaphragms and valve plates employ polymer materials to enhance wear resistance by 30%, ensuring efficient gas flow. Second, the air cylinder accessories adopt a modular structure, allowing flexible component selection. For example, seals with a 25-micron oxide layer support over 2000 hours of continuous operation.

To align with smart manufacturing trends, this pneumatic accessory kit integrates innovative technologies. Core parts are machined with tolerances within ±0.05mm, ensuring seamless compatibility with mainstream oil-free compressor models. Selected components support IoT connectivity for real-time wear monitoring and maintenance alerts. Environmentally, oil-free compressors paired with these air cylinder accessories reduce energy consumption by 15%, helping enterprises achieve green production goals.

The efficient operation of oil-free compressors in medical, energy, and manufacturing sectors relies on high-quality pneumatic accessory support. For instance, laboratory gas analyzers depend on the zero-pollution特性 of the air cylinder accessories to ensure data accuracy. During wind turbine maintenance, high-pressure-resistant cylinders and reinforced screws withstand extreme vibrations. In food packaging lines, antibacterial seals meet hygiene certification standards.

Compared to conventional parts, these oil-free compressor air cylinder accessories cut maintenance costs by 30%. Their standardized design simplifies procurement, eliminating the need to source parts separately for different compressor models, offering a true one-stop solution.

To maximize oil-free compressor performance, inspect valve plates and seals in the air cylinder accessories every 2000 hours. Regular maintenance prevents failures and enhances energy efficiency through pneumatic accessory synergy. High-frequency usage scenarios are advised to stock backup air cylinder accessories to minimize downtime.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

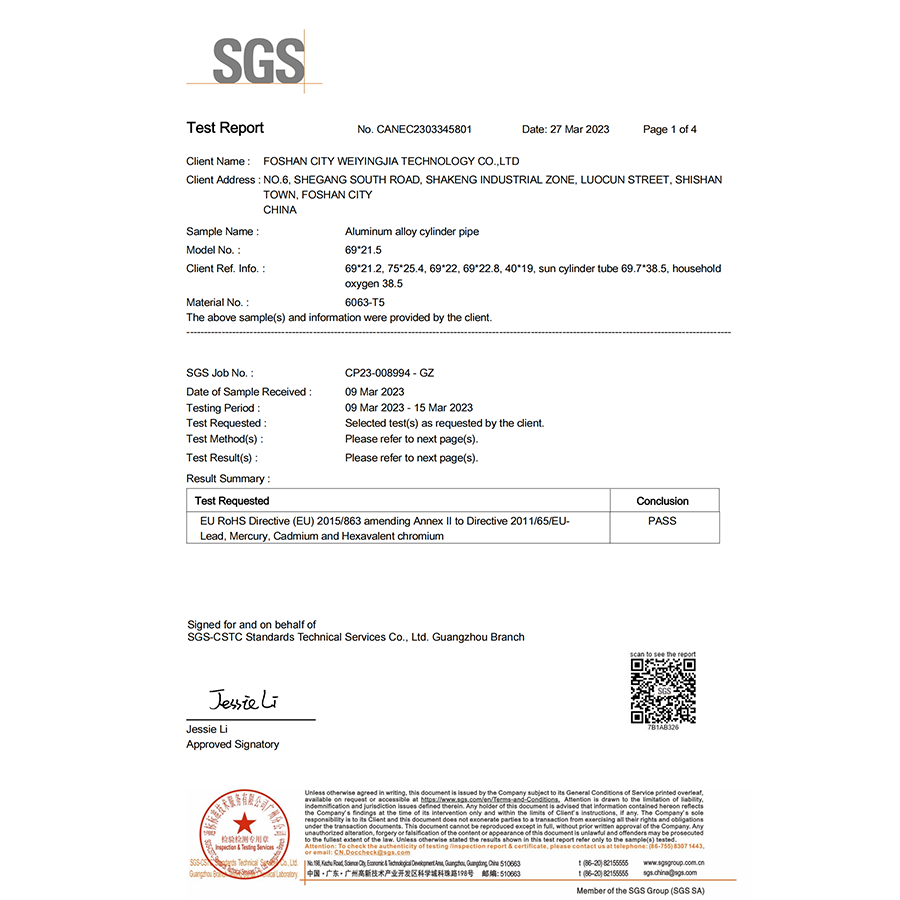

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE