Product Specifications

| Model No.: | TN DUAL AXIS DOUBLE ACTING CYLINDER BARREL | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

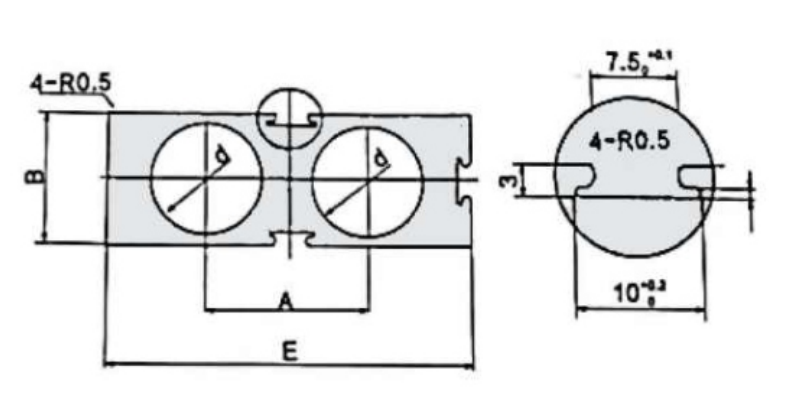

| NO | d | E | A | B |

| 1 | 10 | 42 | 18 | 17 |

| 2 | 16 | 54 | 24 | 21 |

| 3 | 20 | 62 | 28 | 25 |

| 4 | 25 | 73 | 34 | 30 |

| 5 | 32 | 96 | 42 | 40 |

| 6 | 40 | 112 | 56 | 48 |

| 7 | 50 | 135.5 | 60.5 | 58 |

Product Features

TN Dual Axis Double Acting Cylinder Technical Overview

The TN series dual axis cylinder represents a breakthrough in linear motion technology, with its core component—the TN cylinder barrel—engineered for extreme operational demands. Constructed from QT600-3 nodular cast iron through precision centrifugal casting, this double acting cylinder achieves exceptional structural integrity. The TN cylinder barrel undergoes advanced five-axis CNC honing, achieving a surface roughness of Ra0.08-0.2μm, which reduces friction losses by 60% compared to conventional methods. This dual axis cylinder features dual piston rods that deliver synchronized bidirectional force output up to 320kN, effectively resolving torque deflection challenges in heavy-load applications.

Designed for harsh environments, the TN cylinder barrel demonstrates remarkable adaptability. The standard dual axis cylinder operates reliably across a temperature range of -40°C (validated by liquid nitrogen cold-start tests) to 200°C (peak transient), while its double acting cylinder configuration incorporates multilayer nano-insulation to triple seal longevity under thermal stress. For dust-intensive conditions, the TN cylinder barrel integrates a three-stage wiper system compliant with ISO 21007 CLASS 4 standards, coupled with magnetofluidic dynamic seals that maintain >98% filtration efficiency even in environments with PM2.5 concentrations exceeding 500μg/m³.

In industrial applications, the dual axis cylinder excels across multiple sectors. Mining equipment benefits from its IK12-rated impact resistance, with 35-ton excavator arms leveraging the double acting cylinder's bidirectional force to enhance digging stability. Semiconductor manufacturing utilizes the TN cylinder barrel's micron-level precision for chip grinding processes requiring 0.1μm pressure control. Polar research equipment employs specially certified dual axis cylinder units capable of reliable cold starts at -60°C, while explosion-proof variants meet ATEX requirements for hazardous Zone 1 environments.

Smart technology integration elevates the double acting cylinder's capabilities. The TN cylinder barrel now features embedded magnetostrictive sensors achieving 0.001mm displacement resolution, enabling real-time monitoring of piston rod alignment. Through OPC UA protocol compatibility, the dual axis cylinder synchronizes operational data with digital twins, achieving >92% predictive maintenance accuracy based on 100,000-hour performance datasets. Energy optimization systems in the double acting cylinder dynamically adjust hydraulic flow, reducing power consumption by 18% while recovering 30% of kinetic energy through regenerative braking.

Maintenance innovations further distinguish the TN cylinder barrel design. Rapid-seal replacement kits allow dual axis cylinder overhauls within two hours, while laser cladding restoration extends piston rod service life at 65% reduced cost. Optional ceramic coatings boost the double acting cylinder's wear resistance by 400%, ensuring extended durability in abrasive environments.

By combining the dual axis cylinder's force-balanced architecture with the TN cylinder barrel's nano-engineered surfaces, this double acting cylinder series redefines industrial hydraulic performance. Semiconductor wafer-handling robots equipped with these components demonstrate zero precision degradation over 5 million cycles, setting new benchmarks for motion control reliability.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

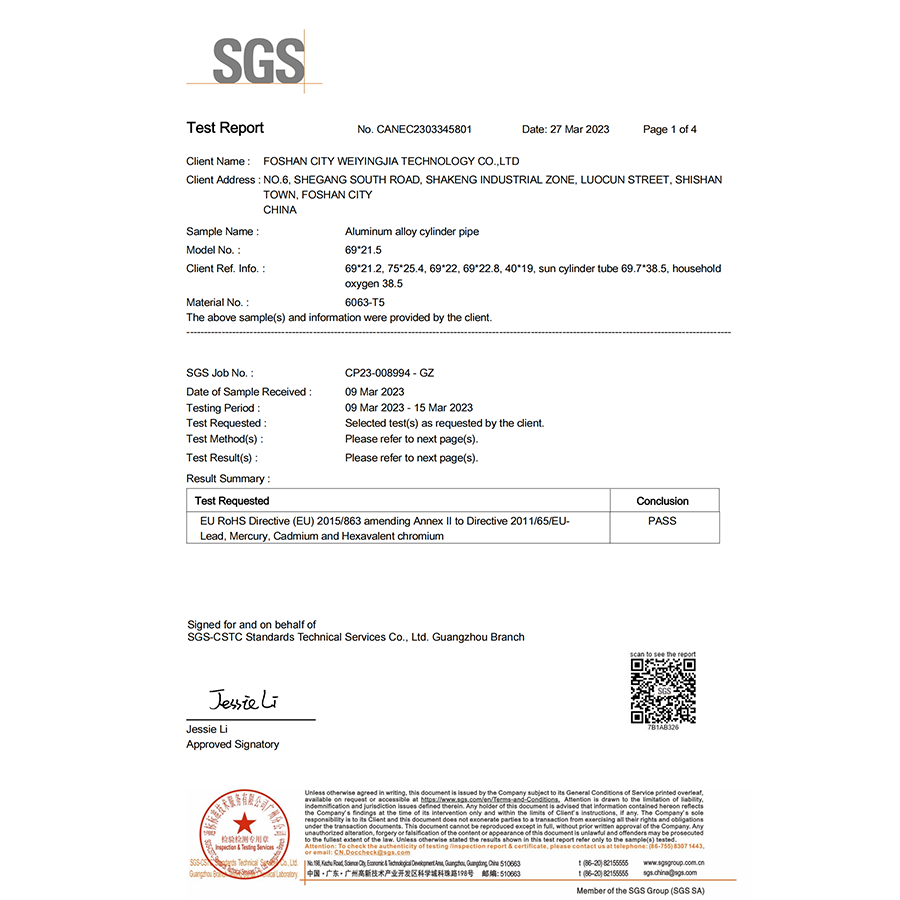

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE