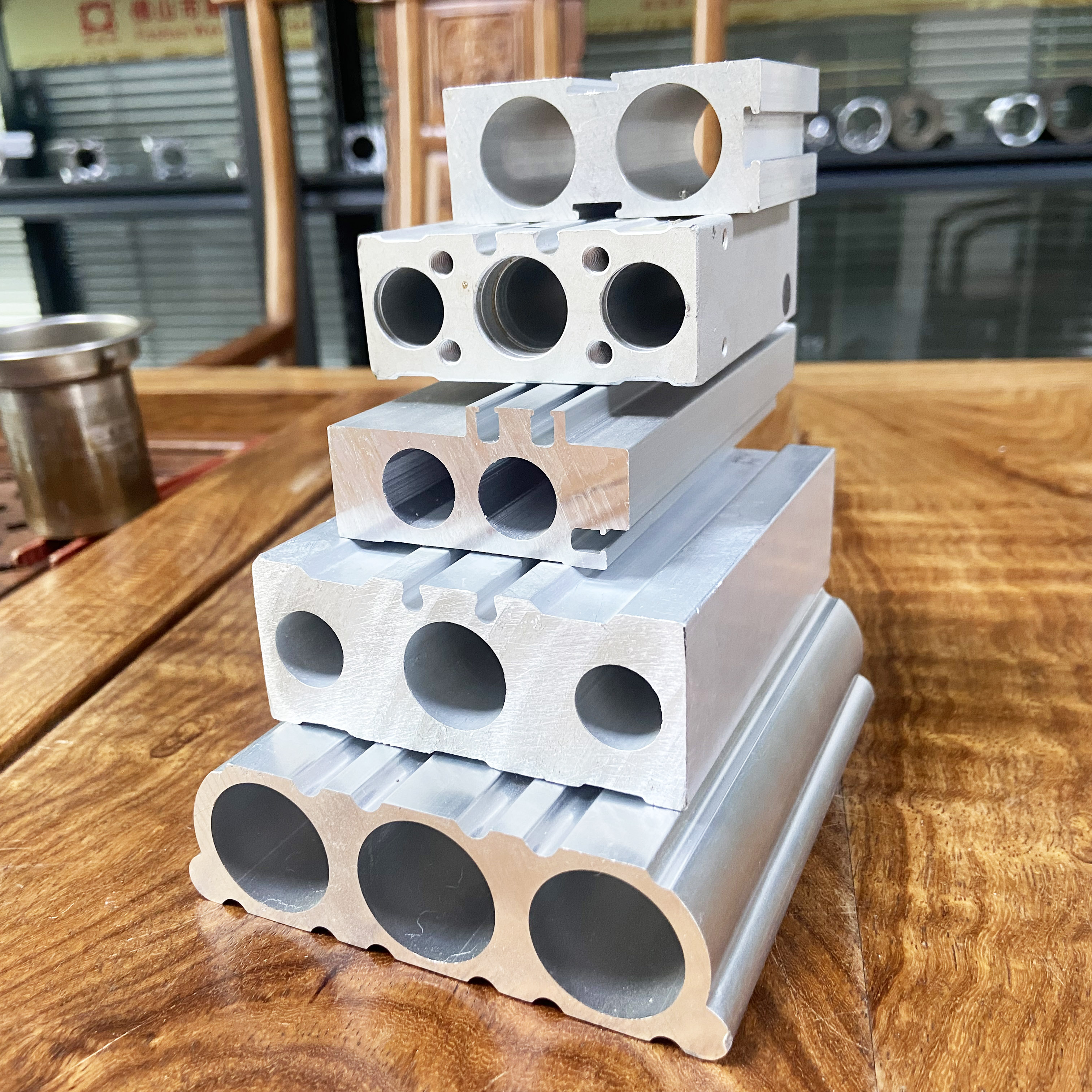

Product Specifications

| Model No.: | TCN THREE AXIS PNEUMATIC AIR CYLINDER BARREL | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

Product Features

TCN Three Axis Pneumatic Actuator System

The structural complexity of the TCN cylinder tube assembly is offset by precision engineering, enabling multidirectional motion control for sophisticated industrial applications. As the cornerstone of the TCN three axis system, this pneumatic solution achieves micron-level positioning through innovative mechanical architecture and advanced material science.

Material Innovation

The TCN pneumatic cylinder revolutionizes traditional designs with aerospace-grade titanium hybrid coatings. Compared to conventional steel cylinders, the TCN cylinder tube achieves 40% weight reduction while demonstrating 5x enhanced salt spray resistance (5,000+ hours ASTM B117 compliance). Surface hardening technology elevates Vickers hardness to HV800-850, extending service life by 300% in abrasive environments. This material breakthrough makes the TCN three axis system ideal for marine, chemical, and high-cycle applications.

Mechanical Architecture

The TCN pneumatic cylinder integrates a patented triaxial guidance mechanism – dual pistons synchronized with three hardened bearing steel rods (HRC60-62). This TCN three axis configuration delivers 1,500N·m torsional rigidity and 0.005mm/m linear accuracy. The TCN cylinder tube incorporates self-lubricating bronze bushings and optional linear bearings, reducing kinetic friction by 62% while maintaining 800kg radial load capacity. Such design ensures the TCN three axis platform withstands combined bending/twisting stresses during 3D contouring operations.

Intelligent Motion Control

Each TCN pneumatic cylinder features embedded magnetic encoder slots and programmable cushioning valves. The TCN cylinder tube's optimized airflow channels enable independent pressure regulation across three axes, achieving 0.01mm repeatability at 150Hz actuation frequency. Modular design allows the TCN three axis system to integrate with robotic arms or CNC stages via standardized ISO 6432 interfaces, reducing installation footprint by 45% compared to conventional multi-cylinder setups.

Performance Validation

Third-party testing confirms the TCN pneumatic cylinder maintains ±0.02mm positional stability under 10G vibration loads. The TCN cylinder tube demonstrates flawless operation across -40°C to 160°C thermal cycles, with IP67 protection against particulate/fluid ingress. In semiconductor wafer handling trials, the TCN three axis platform completed 2 million cycles without maintenance, showcasing its reliability in cleanroom environments.

Application Versatility

From micro-scale TCN cylinder tube modules (15mm bore) for optical alignment to heavy-duty TCN three axis configurations (200mm stroke, 500kg thrust), this system adapts to diverse automation challenges. The TCN pneumatic cylinder's dual-channel feedback supports IoT connectivity for predictive maintenance, while its corrosion-resistant TCN cylinder tube construction meets FDA standards for food/pharmaceutical applications.

Technical Highlights

TCN three axis synchronization error: <0.03° angular deviation

TCN pneumatic cylinder energy efficiency: 35% air consumption reduction

TCN cylinder tube maintenance interval: 50,000km equivalent sliding distance

TCN three axis acceleration: 0-500mm/s in 80ms

TCN pneumatic cylinder MTBF: 60,000 hours (MIL-HDBK-217F)

This TCN three axis pneumatic technology redefines motion control benchmarks, offering manufacturers a cost-effective alternative to servo motors without compromising precision. With 12 modular variants of TCN cylinder tube assemblies and 30+ compatible end effectors, the system provides unparalleled flexibility for Industry 4.0 automation ecosystems.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

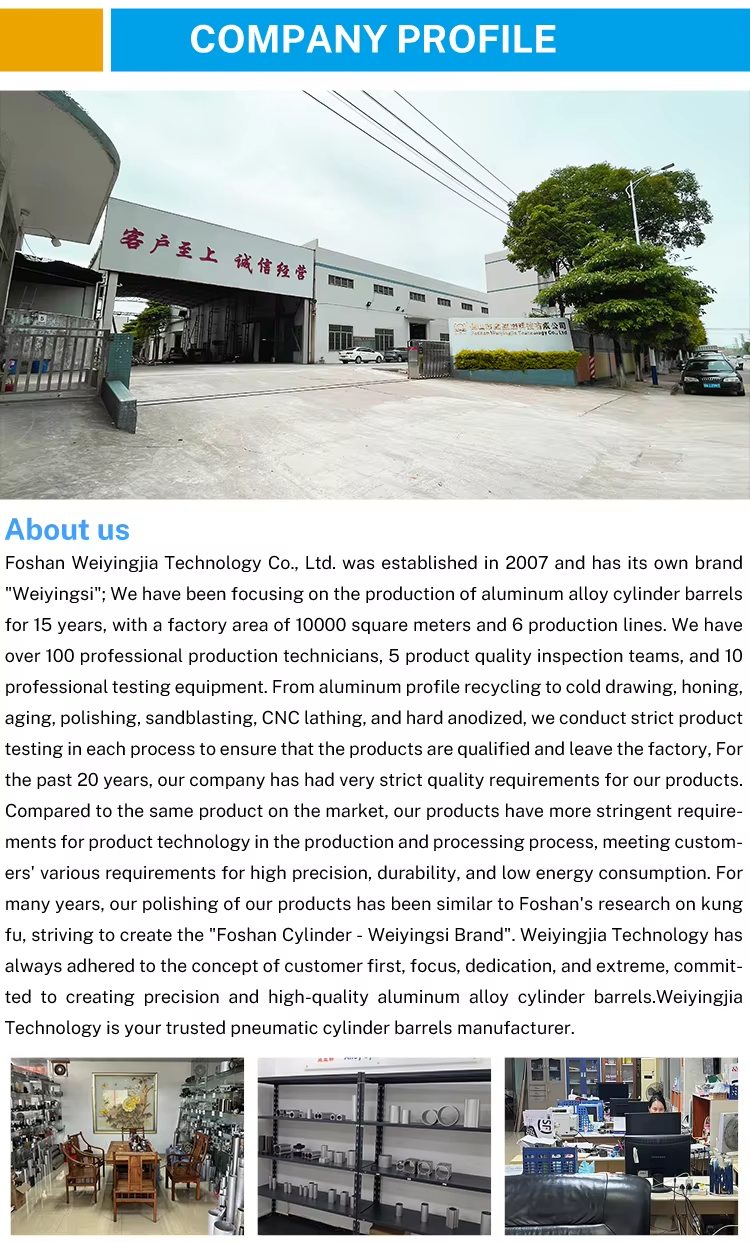

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

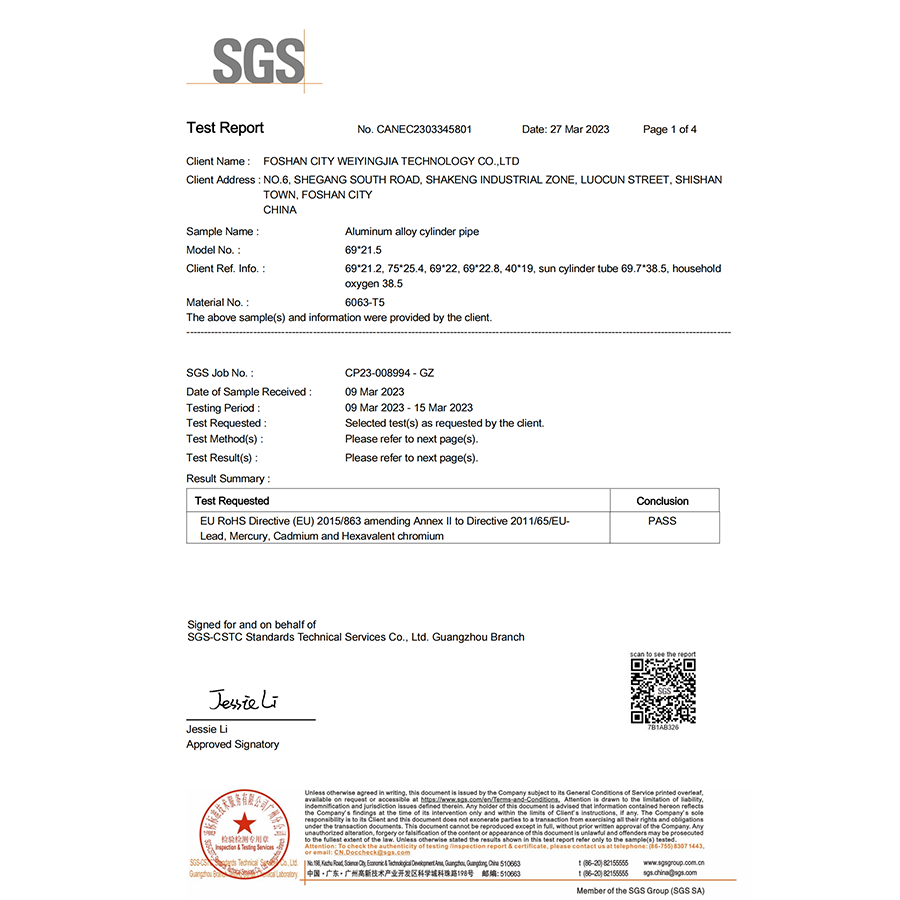

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE