Product Specifications

| Model No.: | AIR WATER OIL PNEUMATIC CONTROL SOLENOID VALVE | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

Product Features

Air-Water-Oil Pneumatic Control Solenoid Valves serve as core components in industrial automation systems, integrating critical technologies such as solenoid valves (electromagnetic valve arrays), pneumatic cylinders, and magnetic valves to enable high-precision fluid control. These systems enhance operational reliability and energy efficiency across power generation, energy extraction, and processing applications.

In large-scale thermal power units, the coordinated operation of solenoid valves and pneumatic cylinders is pivotal for intelligent cooling systems. When abnormal temperature spikes occur, sensors transmit signals to the control unit, triggering rapid state transitions in magnetic valves. Simultaneously, pneumatic cylinders adjust valve openings based on pressure fluctuations to precisely regulate cooling water flow. For instance, retrofitting a supercritical unit with a dual-redundant solenoid valves configuration reduced cooling response time to 0.8 seconds, while closed-loop control via pneumatic cylinders minimized valve positioning errors to ±0.3%. The magnetic valve’s hysteresis compensation further stabilized flow rates, boosting system efficiency by 12%. Modern power plants increasingly deploy multi-channel solenoid valves for distributed cooling medium regulation, supported by magnetic valves’ real-time feedback capabilities.

In long-distance natural gas pipelines, magnetic valves excel in high-pressure gas flow regulation due to their corrosion resistance. Driven by pneumatic cylinders, these valves achieve 20 cycles/second at 5 MPa, while solenoid valves’ pulse modulation ensures 0.1% FS accuracy. At a West-East Gas Pipeline booster station, an 8-unit magnetic valve array combined with pneumatic cylinders’ dynamic balancing algorithms reduced pipeline pressure fluctuations to ±0.05 MPa. In coal liquefaction processes, solenoid valves arrays precisely meter water, oil, and additives, while pneumatic cylinders execute mixing and diversion with 99.7% repeatability. To address harsh environments, self-cleaning solenoid valves maintain reliability in high-dust conditions, with magnetic valves providing fail-safe shutdowns during emergencies.

Under Industry 4.0 frameworks, magnetic valves’ sensing capabilities merge with solenoid valves’ actuation functions. Data from smart substations reveal that self-diagnostic pneumatic cylinder systems optimize solenoid valves’ switching sequences using AI algorithms. When magnetic valve coil temperatures exceed thresholds, systems automatically engage backup pneumatic cylinders and recalibrate solenoid valves’ frequencies, preventing overloads. This closed-loop approach reduced cooling system failures by 40% and maintenance costs by 28%. Advanced multiphysics models for solenoid valves control further cut energy losses by 15-20%, demonstrating how magnetic valves enhance adaptive control networks.

Emerging materials and IoT advancements drive magnetic valves toward miniaturization and hypersensitive detection. Next-gen pneumatic cylinders with graphene composites maintain consistent force output from -50°C to 200°C, while intelligent solenoid valves target sub-5ms response times. In hydrogen storage, magnetic valve-based leak detection modules paired with pneumatic cylinder-actuated emergency shutoffs achieve 99.99% sealing integrity. Digital twin technology now enables real-time optimization of solenoid valves and pneumatic cylinders via virtual prototyping, slashing system tuning cycles. Notably, modular solenoid valves with plug-and-play designs reduce maintenance downtime by 60%, while magnetic valves integrated with wireless sensors enable predictive maintenance across energy grids.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

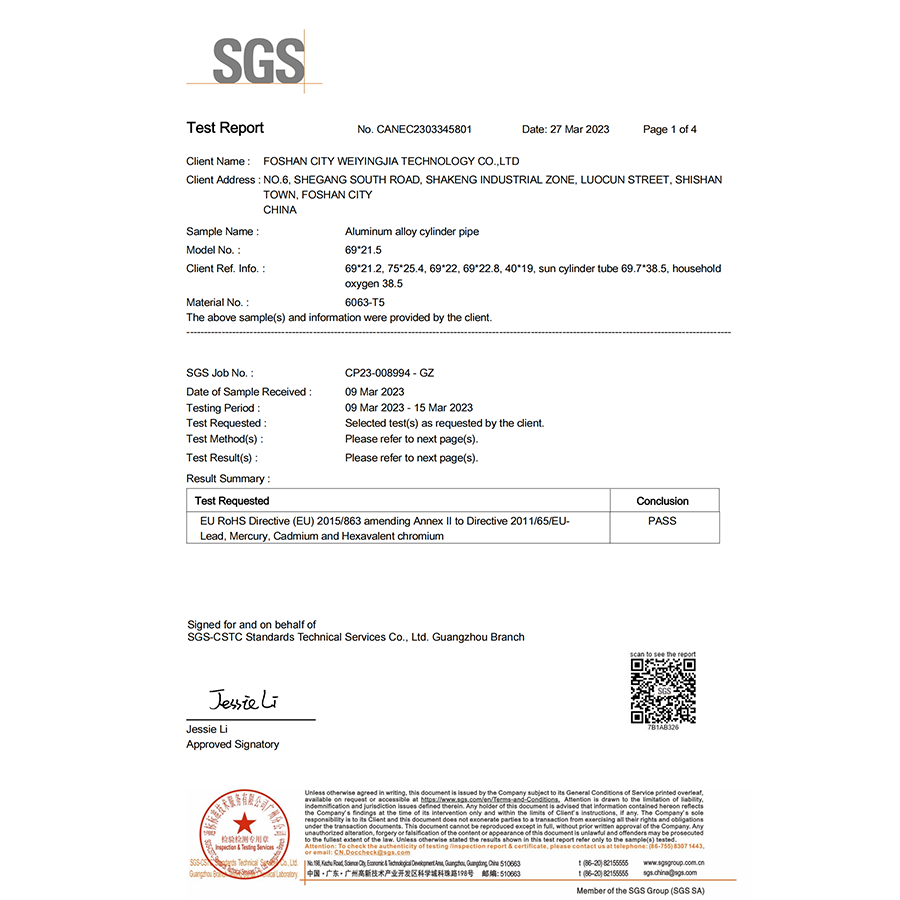

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE