Product Specifications

| Model No.: | S45C HARD CHROME PLATED PNEUMATIC PISTON ROD | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

| Dimension: | 6〜250mm |

| Tolerance: | ISOf7/On request |

| Roundness: | ≤1/2 Diameter tolerance |

| Standard length: | <Φ30mm,2〜3mts/On request cut length ≥Φ30mm,3〜6mts/On request cut length |

| Surface Roughness: | Ra≤0.2 |

| Chrome layer thickness: | Φ<20mm:min.15um Φ≥20mm:min.20um |

| Chrome layer Hardness: | HV850〜 HV1050 |

| straightness: | 0. 15/1000mm |

| Evaluation Corroseston Test: | ISO 10289:1999,IDT |

| Delivery condition: | NORMAL,QT, INDUCTION HARDENED |

Product Features

S45C Hard Chrome Pneumatic Cylinder Piston Rod: Core Component for High-Frequency Applications

The S45C hard chrome pneumatic cylinder piston rod represents a critical engineering solution in modern industrial transmission systems. As a specialized component with multilayer construction, its steel core (typically 42CrMo alloy steel after quenching) is coated with a 20-30μm thick S45C hard chrome layer, achieving exceptional surface hardness of HRC58-62 and tensile strength exceeding 1000MPa.

This enhanced piston rod design addresses the demanding requirements of pneumatic cylinder operations in high-frequency scenarios. The S45C hard chrome coating significantly improves wear resistance while maintaining excellent corrosion protection - particularly crucial for piston rods exposed to compressed air containing moisture and particulate contaminants. When integrated into pneumatic cylinder assemblies, the hardened surface effectively withstands side loads and abrasive wear during repetitive extension/retraction cycles.

In practical applications, the S45C hard chrome pneumatic cylinder piston rod serves as the vital link between pneumatic actuators and driven equipment. One end connects to the cylinder's piston assembly, while the opposite end interfaces with external machinery requiring linear motion. When compressed air enters the pneumatic cylinder chamber, the precisely machined piston rod transmits force with minimal friction loss, converting pneumatic energy into smooth mechanical movement.

Three key advantages make this component indispensable for automation systems:

The S45C hard chrome layer ensures long-term dimensional stability under continuous operation

Optimized surface hardness prevents scoring in pneumatic cylinder guide bushes

High tensile strength withstands dynamic loads in high-speed packaging machinery

Maintenance engineers particularly value the S45C hard chrome pneumatic cylinder piston rod's durability in dusty environments. Unlike standard piston rods prone to rust formation, the chrome-plated surface resists chemical attack from industrial lubricants and airborne contaminants. This characteristic makes it ideal for food packaging lines where frequent washdowns occur.

As manufacturing processes demand higher cycle rates, the S45C hard chrome treatment has become the industry benchmark for premium pneumatic cylinder components. From automotive assembly robots to pharmaceutical filling machines, this advanced piston rod technology continues to drive efficiency improvements across automated production systems worldwide.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

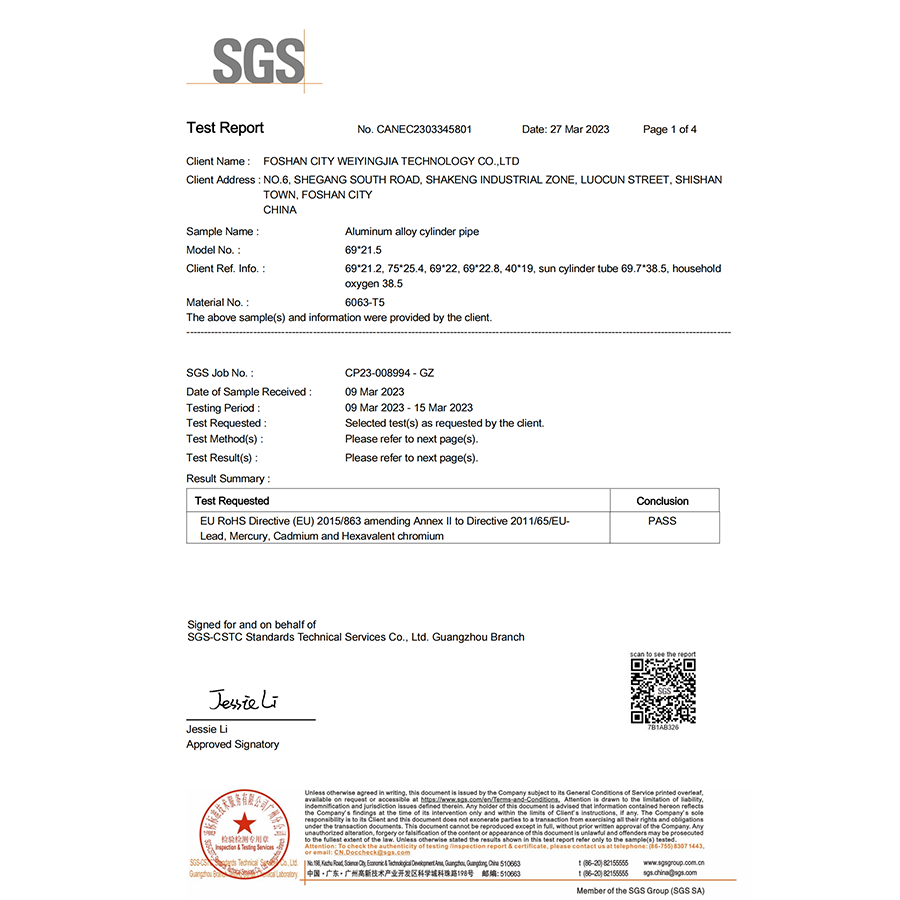

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE