Product Specifications

| Model No.: | MEDICAL OXYGEN CONCENTRATOR MOLECULAR SIEVE CYLINDER | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

Product Features

As an important component of modern medical equipment, oxygen concentrator provides patients with high-purity medical oxygen through innovative gas separation technology. The core component of the system, molecular sieve, is precisely encapsulated in a cylinder tube, and its working principle is based on the significant differences in adsorption characteristics of different gas molecules.

During the operation of the oxygen concentrator, the zeolite based molecular sieve filled inside the cylinder tube plays a crucial role. When ambient air enters the cylinder tube, the molecular sieve preferentially adsorbs nitrogen molecules under high pressure, allowing oxygen to be enriched. Through an intelligent pressure regulation system, the equipment periodically switches the working pressure of the cylinder tube: nitrogen adsorption is completed in the high-pressure stage, and molecular sieve regeneration is achieved in the low-pressure stage. This pressure alternating technology enables molecular sieve to continuously cycle and obtain over 90% medical grade oxygen without the need for chemical additives.

To ensure long-term stable operation, the cylinder tube of the oxygen concentrator adopts an axial reinforced rib design. This innovative structure not only enhances the mechanical strength and fatigue resistance of the cylinder, but also ensures that the molecular sieve bed maintains a uniform compression state during pressure cycling. By optimizing the internal stress distribution of the cylinder tube, the device effectively avoids the gas leakage problem that traditional structures are prone to, resulting in a synchronous increase of about 40% in the adsorption efficiency and service life of the molecular sieve.

In a typical working cycle, the oxygen concentrator achieves continuous oxygen supply through a dual cylinder tube parallel design. When the molecular sieve in one group of cylinder tubes is in the adsorption oxygen production stage, the other group is preparing for regeneration through depressurization desorption. This alternating working mechanism, combined with a precise pneumatic control system, enables the oxygen concentrator based on molecular sieve technology to continuously output high-purity oxygen that meets medical standards 24/7.

With the advancement of materials science, the combination of new composite molecular sieve materials and aerospace grade aluminum alloy cylinder tubes is driving the development of a new generation of oxygen concentrators towards a more compact and energy-efficient direction. This technological innovation not only enhances the oxygen supply guarantee capability of medical institutions, but also opens up new possibilities for the miniaturization of home oxygen therapy equipment.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

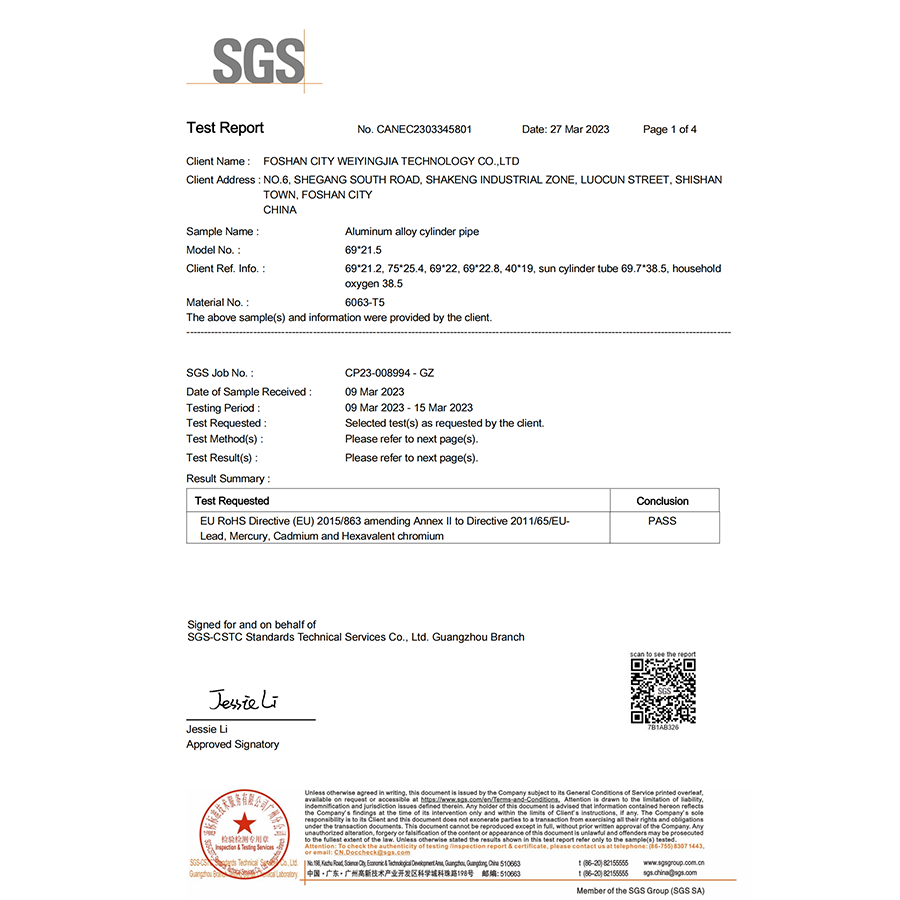

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE