Product Specifications

| Model No.: | DSBC ISO 15552 STANDARD PNEUMATIC CYLINDER BARRELS | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

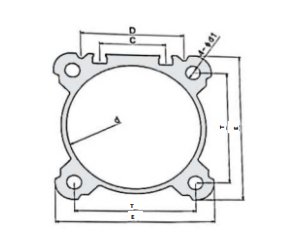

| NO | d | 4-d1 | T | E | C | D |

| 1 | 32 | 5.3 | 45 | 32.5 | 13.5 | 27 |

| 2 | 40 | 5.3 | 53 | 38 | 17 | 34.9 |

| 3 | 50 | 6.8 | 63 | 46.5 | 22 | 38 |

| 4 | 63 | 6.8 | 74 | 56.5 | 31 | 48.5 |

| 5 | 80 | 8.9 | 92 | 72 | 35 | 60.5 |

| 6 | 100 | 8.9 | 109.5 | 89 | 48 | 78 |

| 7 | 125 | 10.3 | 134 | 110 | 54 | 90 |

Product Features

As an industrial grade actuator that complies with the ISO 15552 standard, the DSBC standard cylinder becomes the core power unit of automation systems with its modular design. This series of DSBC pneumatic cylinders adopts a double-layer sealed structure of anodized aluminum alloy DSBC cylinder barrel, combined with high-precision piston rods coated with hard chromium on the surface, which can maintain CRC2 level corrosion resistance under 200 hours of salt spray testing, especially suitable for harsh environments such as shipbuilding and coastal chemical plants.

In terms of energy control, the dual channel pneumatic buffer system configured with the DSBC standard cylinder exhibits significant advantages: the main buffer stroke is 31mm (adjustable range ± 15%), and the auxiliary buffer stroke is 19mm, enabling the DSBC pneumatic cylinder to achieve a kinetic energy absorption rate of ≥ 92% in the speed range of 0.1-1.5m/s. After testing, the model equipped with the reinforced DSBC cylinder barrel (suffix code - BX) can withstand a peak impact force of up to 8500N, meeting the requirements of high load scenarios such as stamping machines and mining machinery.

The installation and maintenance process should focus on the collaborative working status of DSBC cylinder barrel:

Calibrate the coaxiality of the DSBC standard cylinder piston rod and actuator using a laser alignment instrument (deviation ≤ 0.05mm/m)

Inject ISO VG32 grade pneumatic special oil into the DSBC cylinder barrel lubrication groove and replenish oil mist lubrication every 500 hours of operation

Regularly check the exhaust resistance of DSBC pneumatic cylinder buffer valve (standard value 0.15-0.3MPa)

The innovative DSBC standard cylinder advanced version (Pro series) breaks through traditional design:

The inner wall of DSBC cylinder barrel adopts micro arc oxidation process, which increases the wear resistance by 40%

The DSBC pneumatic cylinder with integrated magnetic coupling displacement sensor can provide real-time feedback on piston position (accuracy ± 0.2mm)

Through the EU EN ISO 13849-1 safety certification, it is allowed to directly apply the DSBC standard cylinder to PLd level safety circuits

At present, DSBC pneumatic cylinder has expanded to emerging fields: in lithium battery electrode rolling equipment, the 32mm cylinder diameter DSBC cylinder barrel component can achieve ± 0.01mm dynamic pressure control; The food grade DSBC standard cylinder uses FDA certified sealing materials, and its DSBC cylinder barrel has passed IP69K protection testing, perfectly adapting to the CIP cleaning process of beverage filling production lines.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

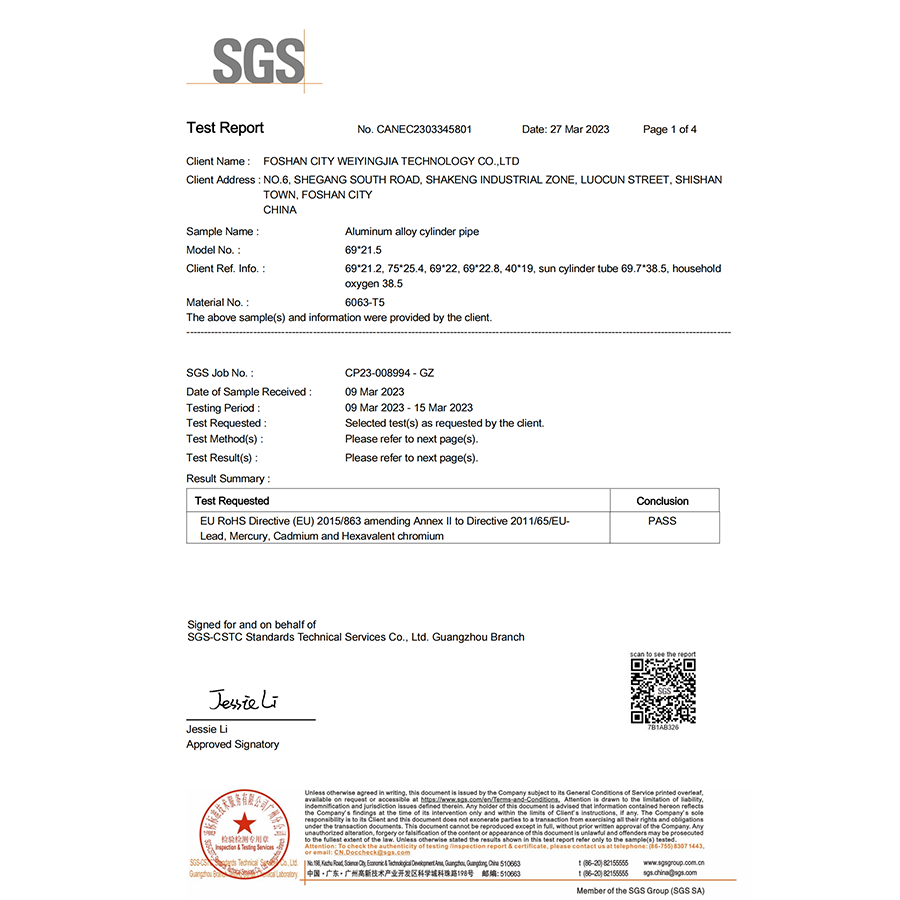

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE