Product Specifications

| Model No.: | SDA COMPACT DOUBLE ACTING CYLINDER BARREL | Brand: | WEIYINGSI |

| Applicable Industry: | Cylinder | Place Of Origin: | FOSHAN,CHINA |

| Inner Roughness: | Ra< 0.4 um | Heat Resistant Temperature: | reach 200 degrees |

| Heat Treatment: | over 4 hour | Honing: | 2 times |

| Anodized Layer: | 15~25 um | Surface treatment: | 100 mesh fine sand |

| Working Pressure: | under 8 Mpa | Hardness: | hv 420 |

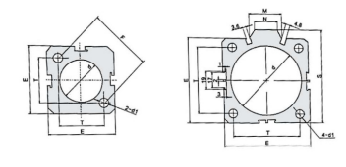

| NO | d | d1 | S | E | T | F | N | m |

| 1 | 12 | 4.3 | 25 | 16.2 | 23 | |||

| 2 | 16 | 4.3 | 29 | 19.8 | 28 | |||

| 3 | 20 | 4.3 | 36 | 34 | 24*24 | 10 | 11.3 | |

| 4 | 25 | 5.2 | 42 | 40 | 28*28 | 10 | 12.3 | |

| 5 | 32 | 5.2 | 50 | 44 | 34*34 | 15 | 18 | |

| 6 | 40 | 6.9 | 58.5 | 52 | 40*40 | 16 | 21.3 | |

| 7 | 50 | 6.9 | 71.5 | 62 | 48*48 | 20 | 30 | |

| 8 | 63 | 6.9 | 84.5 | 75 | 60*60 | 20 | 28.5 | |

| 9 | 80 | 10.4 | 104 | 94 | 74*74 | 26 | 36 | |

| 10 | 100 | 12.4 | 124 | 114 | 90*90 | 26 | 35 |

Product Features

SDA Compact Cylinder: Revolutionizing Ultra-Thin Drive Technology in the Industry 4.0 Era

In the field of precision automation equipment, the SDA compact cylinder is redefining industry standards with its groundbreaking design. As a paradigm of next-generation double acting cylinders, this product achieves a leap in structural performance through its innovative SDA cylinder barrel, whose core technical specifications and industrial application value merit in-depth exploration.

Structural Design Innovations

The SDA cylinder barrel employs a multi-layer composite manufacturing process, covering diameters from 12mm to 100mm, achieving a 70% volume reduction through key advancements:

A piston rod riveting process enhances the concentricity of the SDA compact cylinder to 0.01mm precision.

A triple magnetic coupling array design elevates the positioning accuracy of the double acting cylinder to ±0.2mm.

A carbon fiber-reinforced barrel structure grants the SDA cylinder barrel a bending stiffness of 3,800N/mm².

As a representative of high-performance double acting cylinders, the SDA compact cylinder features three major upgrades to its sealing system:

German-engineered PTFE composite seals expand the operating temperature range of the SDA cylinder barrel to -40°C to 120°C.

Japanese THK self-lubricating bearings enable the double acting cylinder to withstand lateral loads exceeding 5,000N.

A modular quick-release structure reduces maintenance time for the SDA compact cylinder by 83%.

Performance Benchmarking

Comparative testing between traditional double acting cylinders and the SDA cylinder barrel reveals significant advantages:

The SDA compact cylinder delivers 310N/cm force density per unit length, a 158% improvement over conventional cylinders. Its high-frequency response capability reaches 15Hz, triple the industry average, while lateral deflection under full load is reduced to 0.03mm. With a weight coefficient of 0.9g/N, the SDA cylinder barrel achieves unparalleled power-to-weight efficiency.

Industry Applications

In the 3C electronics sector, the SDA compact cylinder has become indispensable for precision assembly:

Apple’s production lines utilize 128 sets of SDA cylinder barrels in micro-force pressing systems capable of 0.005N-level pressure control. Huawei’s 5G base stations employ double acting cylinders for millimeter-precision insertion of RF connectors. Samsung’s flexible display lines rely on SDA compact cylinders to handle 0.1mm-thick OLED panels without damage.

Within new energy vehicle manufacturing, the SDA cylinder barrel enables groundbreaking applications:

CATL’s battery module production lines integrate over 300 double acting cylinders, achieving a cycle time of 2.5 seconds per unit. Tesla’s motor assembly stations use SDA compact cylinders for 0.01g-level dynamic balance adjustments. Bosch’s hydrogen fuel cell stacks leverage SDA cylinder barrels to maintain nanometer-level flatness in proton exchange membranes.

Intelligent Configuration Protocols

To optimize the double acting cylinder’s performance, the SDA compact cylinder requires specialized calibration:

Magnetic sensing systems in the SDA cylinder barrel undergo individual calibration, stabilizing signal strength at 12±0.5mV. Dynamic response is fine-tuned via PID algorithms, with recommended buffer strokes set at 8-12% of total travel. Pre-deployment environmental testing subjects the double acting cylinder to -30°C cold starts and 80°C endurance validations.

Lifecycle Management

Preventive maintenance strategies for the SDA compact cylinder include:

Inspecting seal wear in the SDA cylinder barrel every 500,000 cycles

Replenishing lubricant in the double acting cylinder’s guide bearings quarterly

Annual laser interferometer calibration of the SDA compact cylinder’s positioning accuracy

Failure mode analysis indicates 92% of SDA cylinder barrel malfunctions originate from air supply contamination, necessitating 0.1μm filtration. Electrical failures in double acting cylinders predominantly occur in humid environments, requiring humidity control below 65%. To prevent piston rod micro-deformation, the SDA compact cylinder’s operational load should remain under 80% of rated capacity.

Future Development

Next-generation SDA cylinder barrels will integrate advanced smart features:

Embedded MEMS sensors in double acting cylinders for real-time pressure/temperature/vibration monitoring

AI-driven predictive maintenance algorithms for the SDA compact cylinder, targeting 99% fault prediction accuracy

Graphene-enhanced materials to triple the corrosion resistance of SDA cylinder barrels

Through continuous innovation, the SDA compact cylinder is evolving from a simple actuator to an intelligent drive unit. Across 178 implemented Industry 4.0 projects, production lines utilizing double acting cylinders demonstrate 37% average efficiency gains. With an MTBF (Mean Time Between Failures) of 58,000 hours, the SDA cylinder barrel marks the dawn of a new era in ultra-compact pneumatic technology.

Packaging & Delivery

| Selling Units: | Meter |

| Package Type: | 1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities |

| Picture Example: |  |

Supply Ability

| Transportation | Ocean,Land,Air,Express |

| Supply Ability | 100000Meters/month |

| Port | Foshan,Guangzhou,Shenzhen |

| Payment Type | L/C,T/T,Paypal |

| Incoterm | FOB,EXW |

FAQ

Q: Are you available to supply aluminum cylinder tube samples?

A: Yes, Weiyingjia is able to provide aluminum cylinder tube for you check quality,Normally stock sample is for free for saving your cost, but it will require mold cost if custom tube size.

Q: What’s your MOQ of aluminum cylinder tube?

A: If the require size we have stock.1pcs 2.4meter is ok.

Q: How long time of your aluminum cylinder tube to prepare?

A: It is only taking 7-10 days to complete your sample if the sample size is in stock.For bulk order, lead time according factory production plan, usually 7-25 days.

Q: What is payment terms of aluminum cylinder tube?

A: 30% T/T in advance, the balance payment is paid before shipment.

Q: Which type of surface finishes are you capable to make aluminum cylinder tube?

A: Normally Outer Hard Anodizing, Inner Matt sandy Anodizing.

Q: Are you trading company of factory?

A: We are manufacturer with over 20 years' experience in aluminum product,you will get top quality products and services. We can also OEM and ODM.

Our partners

Package

Qualification certification

SGS testing and certification

QUALITYMANAGEMENTSYSTEM CERTIFICATE